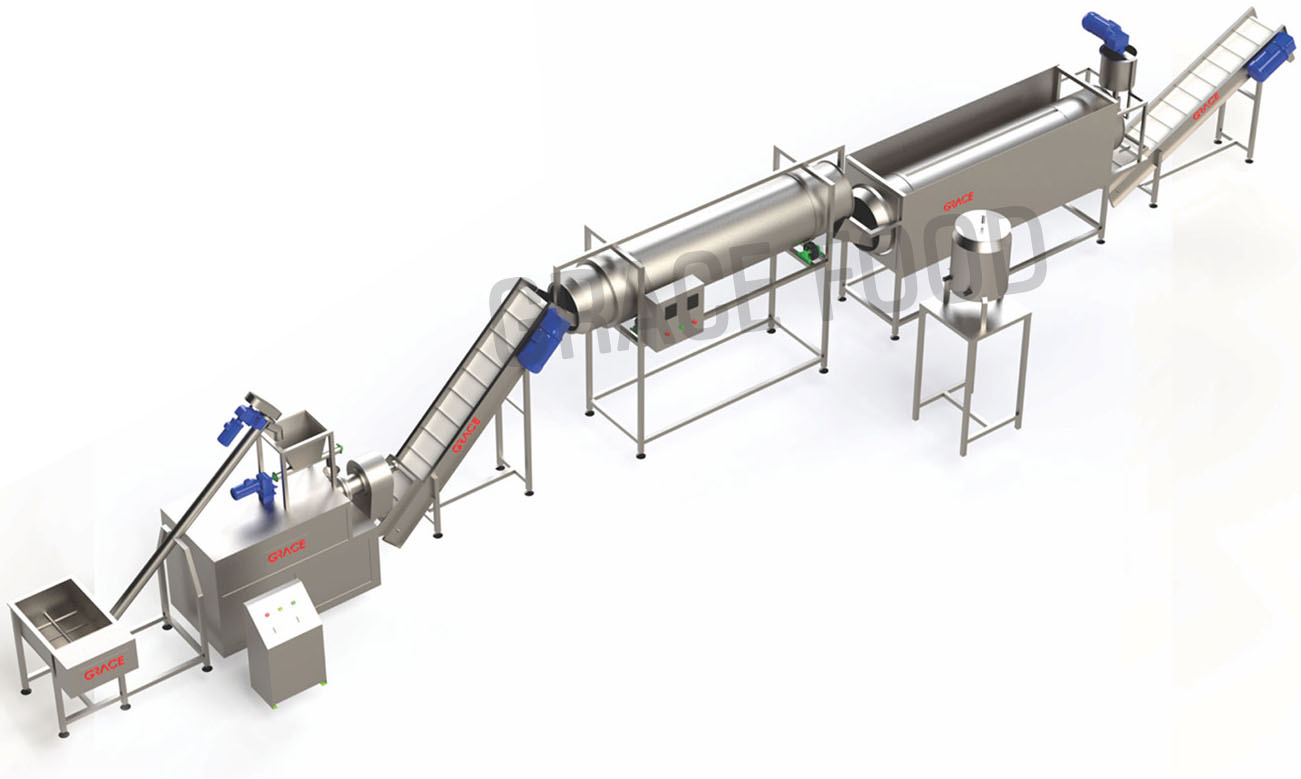

CORN PUFFS LINE

Single Screw Extruder

Grace Food Processing & Packaging Machinery® offer Extruded Corn Snack Production Line in various capacities of corn puffs, corn curl, corn curls, cheese balls shaped snack. Designed as per demand from Extruded Snack Food Industry. Grace Processing & Packaging® work closely with the snack manufacturer and technician to find our problem facing in the Baked Extruded Snacks Processing...

Line at extruded snack industry and come up with well-designed user friendly and low-maintenance Corn Puff Direct Food Extrusion Technology of High shear and high temperature extruder range. Grace Processing & Packaging® are constanly working on provided better solution in the food industry, Our commitment to the industry has revolutionized food production and helped brands create products that consumers love. Invest in machines that are built to last.

Corn Puffs Snacks Processing Line uses corn grit and other ingredients mixed together and extrude through the short screw and high shear model extrusion technology. After extrusion process are precisely baked and proper coating of snacks takes place. This give us crunchy & tasty corn puffs in various shapes. Corn curls, Corn puffs, Grains puffs, Cheese balls, Corn Rings are popular names under this snacks processing line. Snacks Process include precise mixing, dosing of raw materials, cooking and shaping using advanced extrusion techniques to drying and coating.

Technical Specifications

Technical Specifications

| Model | GTL-100-CPLS |

|---|---|

| Output | 100 kg/hr |

| Extruder Type | Single Short Screw |

| Raw Material Type | Corn Grit & etc. |

| Powder Required | 55 HP approx. |

| Floor Space | 1500 Sq. ft. |

| Dryer Heating Option | Electric |

festures

Single Screw Extruder

Single Screw Extruder

Mixer

Our universal mixer, ribbon mixer, can mix a wider range of powder raw materials. A double action ribbon mixes the raw materials while water is gently added. Cleaning of a ribbon mixer is easy and for accessibility it is recommended have a locally built platform.

Extruder: Twin Screw Extruder models

During extrusion, your solid raw materials are mixed, heated, cooked, shaped – all in one process. Our extruder are configured to the specific characteristics of your raw material formulation and the requirement of your end products. We offers various types and capacities in extrusion, our twin screw extruder gives the capacities of 100-150 kg/hr. We offer controls to run the extrusion process for various shapes. All extruders run variable speed, feed control, full water cooled process.

DRYER: belt dryer

The more sophisticated dryer is the belt dryer: drying by hot air. In a heat exchanger, on top of the dryer, hot air is made with a gas or fuel burner or by electricity. Where applicable, heating is always indirect (no fumes to reach the snacks). Hot air is forced through the bed of snacks and returned to the burner, depending on moisture level a percentage of hot air is re-used. The rest is replaced by fresh air.

Flavouring equipment (slurry and dry dosing)

Snacks need a coating to become attractive, this is done in a coating drum immediately after drying. The coating drum comes in various sizes and has on the inside a self-cleaning profile. To ensure uniform residence time, strips are mounted in the drum. The rotation speed of drum are variable.

Slurry Preparation

Coating is done by slurry: the mix of oil and flavour powder. For this purpose the slurry mixer and spraying attachments.

Buffer silo

A very smart solution to cope with the huge volume flow coming from the extrusion line. It is not recommended to stop (or reduce) the extruder capacity. Most effective and efficient is to leave the equipment running, producing the required snacks and just collect them in a buffer silo, prior to packaging. We use the vertical buffer silo with vibration feeder at the exit. You can also opt for belt bunkers and other types of buffers. It is vital here that the system is closed to limit exposure of snacks to outside air and humidity.