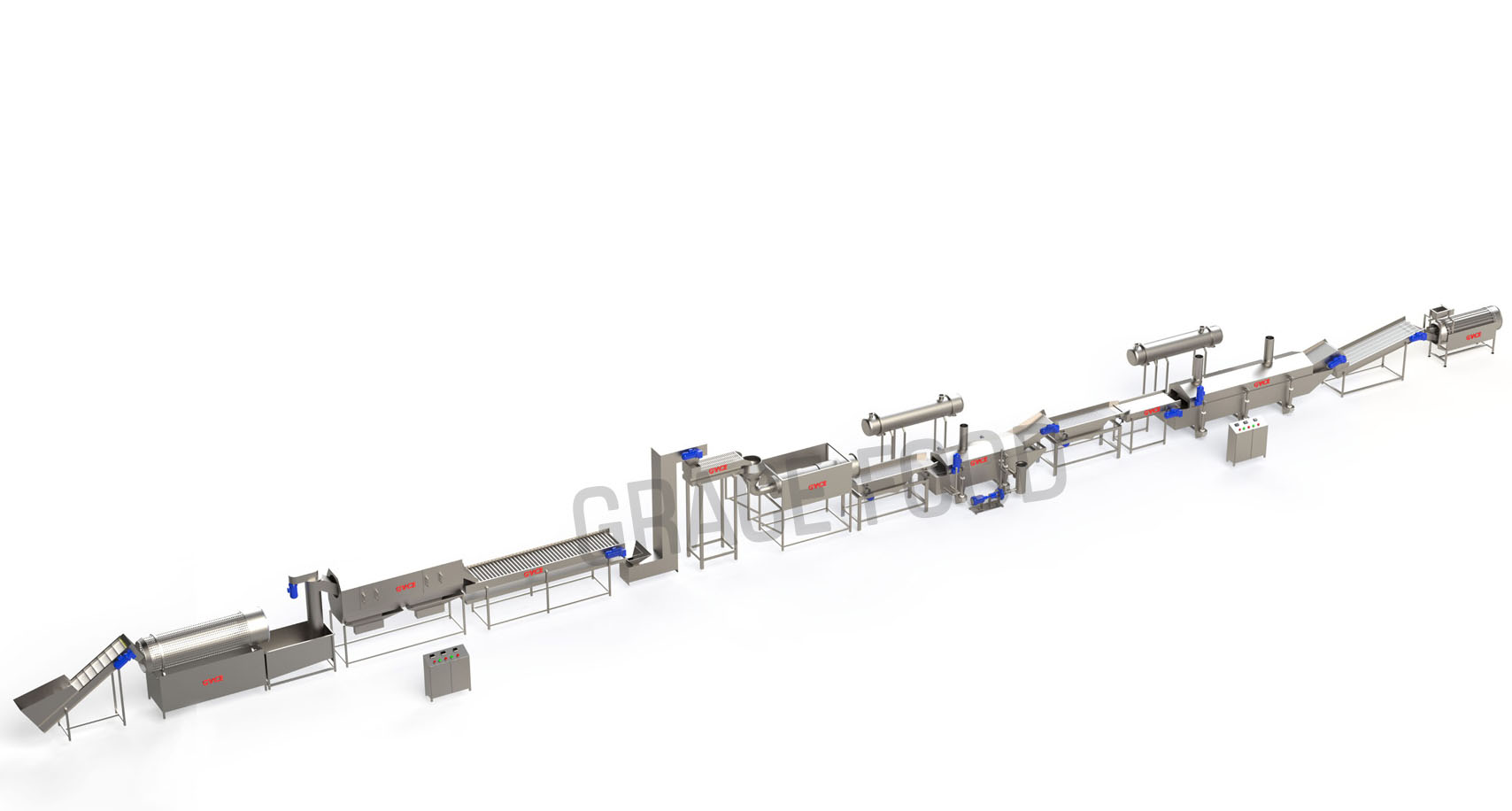

Automatic Potato Chips Line

Grace Processing & Packaging® offers Automatic Potato chips production line to manufacture crispy and tasty potato chips. Our Chips production plant is produces quality potato chips which brings value to our customer. Potato processing machinery designed precisely to get world most famous snack food potato chips. Complete Potato Processing Lines for Potato Chips to get Tasty Potato Crisps from Fresh Potato From The Farm with Grace Processing & Packaging® equipment.

We provide turnkey potato processing products solutions to ensure optimal production throughout the line. Our solutions include all the necessary equipment from raw potato input to packaging. We have designed the potato chips production are deep-fried and delicious snack with perfection with small detail. Our heat transfer technology combined the potato frying system provide the contact temperature with small fluctuation to the frying oil which ensures an even fried chips end product. Our frying system required low oil content and low frying oil turnover time.

We have developed the perfect transportation system for the potato chips slice through the fryer, which ensures every single pieces of product get same retention time and no possibility to escapes from the laminar flow of frying oil and no possibility to escapes the flow to stay behind and get over cooked.

Grace Processing & Packaging® machinery recommend to use blancher to reduce the sugar content from the potato slices to prevent quick dark colouring of the slices. Some manufacturers are using a conditioner with chemicals to prevent dark colouring of the slices. We believe a natural product is the desired product by the consumer, therefore avoid any chemicals in our process.

Technical Specifications

Technical Specifications

| Model | GTL-300-PCL | GTL-500-PCL | GTL-500-PCL |

|---|---|---|---|

| Output | 300 kg/hr | 500 kg/hr | 1000 kg/hr |

| Power Required | 70 HP approx. | 90 HP approx. | 130 HP approx. |

| Floor Space | 3000 Sq. ft. | 4000 Sq. ft. | 6000 Sq. ft. |

| Water Required | 2000 liters / hr | 3000 liters / hr | 5500 liters / hr |

| Material of construction | AISS-304 Grade SS | AISS-304 Grade SS | AISS-304 Grade SS |

| Oil Heating Fuel Option | Diesel or Gas | Diesel or Gas | Diesel or Gas |

festures

Single Screw Extruder

Single Screw Extruder

Mixer

Our universal mixer, ribbon mixer, can mix a wider range of powder raw materials. A double action ribbon mixes the raw materials while water is gently added. Cleaning of a ribbon mixer is easy and for accessibility it is recommended have a locally built platform.

Extruder: Twin Screw Extruder models

During extrusion, your solid raw materials are mixed, heated, cooked, shaped – all in one process. Our extruder are configured to the specific characteristics of your raw material formulation and the requirement of your end products. We offers various types and capacities in extrusion, our twin screw extruder gives the capacities of 100-150 kg/hr. We offer controls to run the extrusion process for various shapes. All extruders run variable speed, feed control, full water cooled process.

DRYER: belt dryer

The more sophisticated dryer is the belt dryer: drying by hot air. In a heat exchanger, on top of the dryer, hot air is made with a gas or fuel burner or by electricity. Where applicable, heating is always indirect (no fumes to reach the snacks). Hot air is forced through the bed of snacks and returned to the burner, depending on moisture level a percentage of hot air is re-used. The rest is replaced by fresh air.

Flavouring equipment (slurry and dry dosing)

Snacks need a coating to become attractive, this is done in a coating drum immediately after drying. The coating drum comes in various sizes and has on the inside a self-cleaning profile. To ensure uniform residence time, strips are mounted in the drum. The rotation speed of drum are variable.

Slurry Preparation

Coating is done by slurry: the mix of oil and flavour powder. For this purpose the slurry mixer and spraying attachments.

Buffer silo

A very smart solution to cope with the huge volume flow coming from the extrusion line. It is not recommended to stop (or reduce) the extruder capacity. Most effective and efficient is to leave the equipment running, producing the required snacks and just collect them in a buffer silo, prior to packaging. We use the vertical buffer silo with vibration feeder at the exit. You can also opt for belt bunkers and other types of buffers. It is vital here that the system is closed to limit exposure of snacks to outside air and humidity.